Definition of Rotary Drive

1. Definition of Rotary Drive

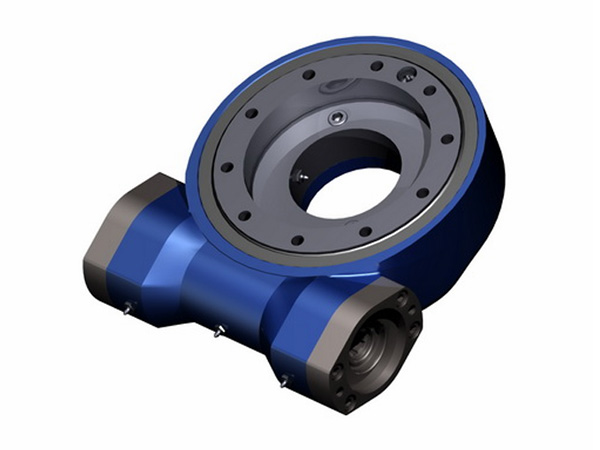

Rotary drive device is a new type of rotary product, which is also called slewing support. It is usually composed of worm, slewing support, shell, motor and other components. Because the core components are supported by slewing, they can bear axial force, radial force and overturning moment at the same time. Compared with traditional rotary products, rotary drive has the advantages of simple installation, easy maintenance and more space saving. This product can be widely used in the field of construction machinery and new energy, such as heavy flat-plate truck, container crane, on-board crane, aerial working vehicle, solar power generation system, etc.

2. Rotary drive structure

Rotary drive can be basically divided into single worm drive, double worm drive and special type of rotary drive.

3. Three Advantages of Rotary Drive

Modularization

Because of the high integration of rotary drive, users do not have to purchase and process each part of the rotary device one by one. To a certain extent, the preparation process at the beginning of production is reduced, thus greatly improving labor productivity.

Safety

Worm wheel and worm drive has the characteristics of reverse self-locking, which can realize reverse self-locking, that is, only worm can drive worm wheel, but not worm wheel can drive worm motion. This characteristic makes the rotary drive widely used in lifting, high altitude operation and other equipment. It not only improves the technology content of the main engine, but also greatly improves the operation stability and safety factor of the main engine. Compared with traditional rotary products, rotary drive has the advantages of simple installation, easy maintenance and more saving installation space.

Simplified host design

Compared with the traditional gear transmission, worm gear transmission can get a relatively large deceleration ratio. In some cases, reducer components can be omitted for the main engine, thus reducing the procurement cost for customers, but also greatly reducing the failure rate of the main engine.