Why do we need preheat treatment in the production of rotary bearing?

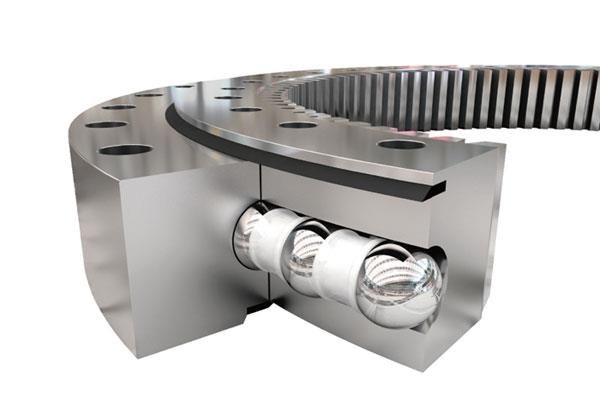

Rotary bearing is one of the most important parts in machinery. It needs to be preheated when it is used. Why should it be preheated when it is used? Let's analyze the reasons below.

Benefits of preheating rotary bearing:

1. It can make the stability and uniformity of the rotary bearing better. Because the preheating transformation is a relatively slow process, generally speaking, the BL transformation of the rotary bearing is about 4 hours, and the surface structure transformation is almost simultaneous, so if preheating, the hardness stability and uniformity of the rotary bearing will be better.

2. It can reduce the grinding cracks of rotary bearing. In the production of turntable bearings, because of the large size and heavy weight of rings, brittleness will be greater when quenching. In order to ensure the quality of quenching, strong cooling measures will be adopted, which may lead to quenching micro-cracks. The preheated structure is much tougher than the M structure, and the surface can form a pressure change of - 400 - 500 MPa, which can greatly reduce the appearance of quenching grain.

3. Improve the service life of rotary bearing. For turntable bearings with large load-bearing in mechanical parts, the wear and tear is more serious in use, so the toughness of the bearings treated by isothermal quenching will be better, and the service life of the pre-heat-treated turntable bearings will be greatly improved.

The above three points are the reason why pre-heat treatment should be carried out in the production of rotary bearing. More knowledge about bearing manufacturing is welcome to visit our website.